Transport aircraft deliver supplies to the armed forces, even in the remotest of locations. This is a vital task that hinges crucially on how familiar the operators – from the pilot down to the mechanic – are with the particular aircraft. Simulation technology from Rheinmetall ensures that these professionals receive the very best training.

Whether engaged in collective defence on the outer edges of NATO or rapid response missions on faraway continents, armed forces worldwide need supplies. This is where tactical and strategic air transport, for one, comes in. European NATO countries use various types of transport aircraft for this purpose. These include the A400M, which is currently operated by Belgium, Germany, France, the UK, Luxembourg, Spain, Turkey, and Malaysia – with more nations to follow. Germany and France are also forming a joint C-130J squadron. Portugal, Hungary, and the Netherlands will soon deploy the KC-390.

Tried-and-trusted simulation technology from Rheinmetall is used to train the professionals who fly and maintain these aircraft, and to keep them up to speed. “Realistic training systems deliver a comprehensive training experience that doesn’t depend on the original equipment being available,” says Doris Lilkendey, head of the flight simulation products unit at Rheinmetall Electronics, explaining the purpose of the cutting-edge simulators. “Training – even for complex scenarios and emergency situations – can be provided in a safe environment. This means that military personnel are well prepared and well skilled when they go out on their missions.”

Simulation technology covers a broad range, from simple tutorials that can be augmented with state-of-the-art mixed reality technology through to true-to-scale replicas (such as the Training Rig) and complex pilot training in Full Mission Flight Simulators in the premium class. “We are the expert training partner for tactical and strategic air transport,” insists Doris Lilkendey.

Partner for aircraft manufacturers

A close partner of Airbus, the A400M’s manufacturer, Rheinmetall plays a key role in training the crews of the European transport aircraft. The same goes for the C-130J produced by Lockheed Martin. As one of the company’s official subcontractors, Rheinmetall, along with Thales France, has been tasked with certifying and operating the future training centre for the Franco-German C-130J transport aircraft squadron. Certification of the Évreux-based training centre as an Approved Training Organization (ATO / MTO) involves setting up the training organization and subsequently conducting training operations from the end of 2023 onwards with a team of highly skilled instructors.

The long-established aircraft maker Embraer of Brazil has contracted with Rheinmetall to develop and supply all the training equipment for the new KC-390 transport aircraft. This covers the entire spectrum of crew training, from Cargo Handling Station Trainers and Cockpit Procedure Trainers, right through to the Full Mission Flight Simulator, which faithfully simulates all the aircraft’s functionalities and provides the full range of training options. “With our Full Mission Flight Simulators for the KC-390, we have hugely broadened our range of expertise to include pilot training for complex transport aircraft,” says Lilkendey.

Training in authentic surroundings

For practical training of technical cargo handlers and the air-handling staff who operate on transport aircraft, using full-scale equipment is the ideal solution – including the various cargo hold simulators that Rheinmetall has already supplied to almost all the user countries listed above, including for the A400M project. The company has accumulated over 40 years of expertise in simulation technology and is the global market leader in Load Master Workstation Trainers (LMWST) and Cargo Hold Trainers (CHT) for the A400M transport aircraft.

The systems are suitable for basic and advanced training as well as recurrent training and pre-deployment preparation. They also allow difficult manoeuvres such as airdrop procedures to be practiced in complete safety. “The essential purpose of the CHT-E(nhanced) – the highest configuration level – is to provide cargo hold and ground-handling crews realistic with training without having to take up valuable aircraft operating hours,” explains Doris Lilkendey. “The programme includes mission-specific reorganization of the cargo hold, preparation of cargo, loading and unloading, standard in-flight and ground tasks, as well as cooperation between multiple crews.”

The German Airborne Operations and Air Transport School at Altenstadt in Upper Bavaria took delivery of an A400M Cargo Hold Part Task Trainer (CPTT) at the end of September 2022. A second is soon to enter operation at Germany’s Air Transport Wing 62. The CPTTs are tailored to the specific missions of the training institutions. They also allow procedures and configurations for new types of cargo to be evaluated, tested, and verified.

The company has successes to report in the premium class as well. Factory acceptance testing of the first KC-390 Full Mission Flight Simulator was successfully carried out in August 2022 at the Rheinmetall’s plant in Bremen. “The test pilots from Brazil are ecstatic,” reports Lilkendey. “Portuguese and Dutch pilots have also flown the KC-390 in our simulator already and were highly impressed – both with the aircraft and our simulators.” KC-390 pilots receive realistic training in the Full Mission Simulator (FMS), ranging from handling the aircraft and practicing emergency procedures to training for complex mission scenarios, including in-flight refuelling. The FMS was developed in line with international EASA and FAA training standards and will be certified to the highest standard, Level D. Hard on the heels of Brazil, the first customer, Portugal has placed an order for the FMS as well.

Rheinmetall simulation technology

For transport aircraft:

• Embraer KC-390

• Airbus A400M

• Lockheed Martin C-130J

For helicopters:

• NHIndustries NH90

It looks like a scene from a science fiction movie: an ordinary car driving through the streets, braking for passers-by who want to cross the road – it’s just that there’s no driver.

(On top: Everything under control: The control station makes it feel like you’re sitting in an actual car. For Mira development engineer and teleoperator Wojciech Stepniewski, even the mirror views from the teleoperated vehicle are transmitted in real time.)

Vehicles seemingly controlled by invisible hands are by no means a distant prospect. Soon they’ll be part of every cityscape – and not just in the current pilot regions in Düsseldorf- Derendorf and the city’s industrial port, which have been approved as real-life laboratories by TÜV Rhineland and Düsseldorf, home to Rheinmetall and the state capital of North Rhine-Westphalia.

Teleoperated driving technology makes this possible. The vehicle is equipped with a built-in remote-control function (steer-by-wire) and various cameras. The “driver” sits remotely in a control station that contains all the functions and control units of a normal car. The view from the vehicle – including the side and rear-view mirror views – is shown on large monitors. A crucial safety factor: the camera images and all the driver’s decisions are implemented in real time thanks to state-of-the-art 5G mobile communications technology. The view from the vehicle – including the side and rear-view mirror views – is shown on large monitors. A crucial safety factor: the camera images and all the driver’s decisions are implemented in real time thanks to state-of-the-art 5G mobile communications technology.

The interdivisional pre-developers strive to anticipate or recognize future technological trends and to design the resulting innovations to the point where they can be handed over to the relevant Rheinmetall development unit or, for example, to a joint venture, which will then assume responsibility for further development, marketing and, ultimately, industrialization of the project. The RTC, which forms part of Rheinmetall’s central “Research, Technology and Innovation” unit, is headed by Heinrich Dismon and Klaus Kappen, the chief technology officers of Rheinmetall’s civil and military sectors.

The interdivisional pre-developers strive to anticipate or recognize future technological trends and to design the resulting innovations to the point where they can be handed over to the relevant Rheinmetall development unit or, for example, to a joint venture, which will then assume responsibility for further development, marketing and, ultimately, industrialization of the project. The RTC, which forms part of Rheinmetall’s central “Research, Technology and Innovation” unit, is headed by Heinrich Dismon and Klaus Kappen, the chief technology officers of Rheinmetall’s civil and military sectors.

A WIDE RANGE OF APPLICATIONS

Due to the diverse range of potential users of teleoperated driving, Dismon sees excellent market opportunities for the new technology in the civil sector. Potential users and applications include car rental companies and shuttle services, logistics and transportation firms, local public transport, commercial and special vehicles as well as airports, ports, power plants and mines. There are also applications in the private sphere, where drivers may not want to be at the wheel themselves or simply wish to teleoperate their vehicles and park them in the nearest parking lot.

“But we also see realistic possibilities for use in the military domain,” adds Kappen, “such as logistics vehicles or in particularly critical areas.”

In addition to the necessary control and safety equipment manufactured by the Group and teleoperated movement of vehicles, the Düsseldorf-based company’s portfolio also includes tele-assisted driving. For example, artificial intelligence in a fully autonomous vehicle may face a problem if it needs to cross a solid line due to a specific certain traffic situation, which is normally a no-go for the autonomous control system. “In such cases, a human could intervene as a tele-assistant and take care of the situation,” says Kappen. “We have to have a technical supervisor who can step in as needed. Thanks to the bridging technology of tele-assisted driving, level 4 or 5 autonomous driving is quickly becoming a viable prospect,” he says.

However, this future-oriented technology should not and cannot be brought to market by Rheinmetall alone. This is where Mira GmbH comes in. This recently founded Rheinmetall subsidiary will soon be offering a wide range of products and services related to teleoperated driving for the civilian sector, which incidentally is a precondition for bringing external partners onboard.

LOTS OF ARROWS IN THE QUIVER

The RTC is also active in other civil and defence technology projects. Tool-based reporting and regular meetings with relevant developers on site ensure that research is not conducted in an ivory tower but is instead linked with the operational units to the greatest extent possible. Kappen: “Potential benefits of the RTC’s developments are continuously scrutinized in the Group’s management committees.” In addition, substantial sub-developments – such as teleoperated driving – are already under way in various operational divisions of the Rheinmetall Group. These include the visual system (Electronics Solutions) and the hardware and operating software for vehicle control (Vehicle Systems).

Other activities of the RTC’s 35-strong staff include development of new countermeasure systems for the navy, improvement of charging infrastructure for electric vehicles in urban areas, and camera- and radar-based monitoring of vehicles. The latter is about to become a legal requirement in the United States, mostly as a means of making sure children or pets aren’t forgotten or unintentionally left behind in cars. For car manufacturers, this is an important feature that also earns points in the Euro NCAP test. Artificial intelligence is also used here, whether simply for detecting the presence of people in the vehicle or for monitoring the driver to ensure that he or she is fit to drive. This technology, which is at an advanced stage of development, is currently being handed over to the Sensors and Actuators division.

The RTC will initially provide support, but the division will eventually assume responsibility for further development and, ultimately, commercialization. There are numerous other potential uses for these applications in the civil and military sectors. These include vehicle access control, passenger status (strapped in?/ healthy and fit to drive?) or intrusion detection, to name but a few. Reason enough for Rheinmetall to have recently entered a joint venture with DERMALOG Identification Systems GmbH, Germany’s largest biometrics company. Reason enough for Rheinmetall to have recently entered a joint venture with DERMALOG Identification Systems GmbH, Germany’s largest biometrics company.

PILOT PROJECTS FOR CHARGING INFRASTRUCTURE

Where’s the nearest charging station? Is even it available? How much farther can I drive? Anyone who’s ever driven an electric car is familiar with these concerns, especially as the current number of charging options in our inner cities – though steadily increasing – is still nowhere near the level where we wouldn’t have to worry about where the nearest one was. This is where the RTC comes in with a concept for solving availability issues in inner cities – after all, lack of space means that it’s often not even possible to construct enough conventional charging stations.

Curb creates remedy

A curb side charging system could provide a comparatively quick and easy remedy. The idea is to turn entire streets with on-street parking into a power source with up to 22 kW of charging power. Initial internal tests received highly positive feedback, and some cities are already interested in installioning pilot charging facilities of this kind in partnership with the RTC. Drivers of electric vehicles will certainly be grateful.

WHAT MIRA WILL OFFER

• Tamper-proof real-time vision systems for vehicles

• Functional safety and system security of control units

• Control stations with technical supervision for autonomously operated vehicles (SAE L4/L5)

• Control stations for teleoperated vehicles

• Cyber units for video, control and personal data security

• Full installation and integration

• Commissioning/provision of required services

• Homologation and certification of driverless vehicles

• Staff training

Featuring superb protection, this unique all-terrain vehicle assures exceptional operational effectiveness in critical situations. No wonder Germany’s public order police units are equipped with the Survivor R, which will soon be part of the German Federal Police fleet as well. And now the special response vehicle is starring in RTL’s long-running TV series “Alarm for Cobra 11.”

A roar of engines and flashing blue lights; doors burst open, stun grenades fly. A dark-blue armoured vehicle pulls up, tyres screeching; armed officers jump out and charge forward: “Police! Freeze!” This exciting scene shows what Rheinmetall’s Survivor R protected special response vehicle can do, but it is not taken from real life. It’s a clip from the film “Unversöhnlich” (Unforgiving), part of RTL’s hit series “Alarm for Cobra 11”, starring Erdogan Atalay as Detective Chief Inspector Semir Gerkhan.

Fiction and facts

Nowadays, most TV crime shows bear little resemblance to the everyday reality of police work. But the Survivor R is ready for action whenever it looks like things might get dicey – for example, when officers have to arrest particularly “violent counterparts” – officialese for crooks – or rescue people in dangerous environments.

German federal and state police agencies have traditionally been equipped with specially protected vehicles – known as “Sonderwagen” or “SW” for short – for operations like this. Most law enforcement agencies still use the Sonderwagen 4. But this tried-and-trusted vehicle, developed at the end of the 1980s, is getting a bit long in the tooth, leading Germany’s federal police agency and state-level public order police units to look for a replacement. The Survivor R was selected in a Europe-wide call for tenders starting at the end of 2021. The procurement agency of Germany’s Federal Interior Ministry has ordered 55 of the all-terrain, protected multipurpose vehicle in different variants for the German Federal Police and the public order units of Germany’s state-level police forces, with an option to purchase further units. In a first step, Rheinmetall and its cooperation partner Achleitner will supply two sample vehicles, which will undergo extensive trials, including full certification of the protection features. Delivery of the production vehicles is expected to begin in 2023 and to be complete by 2026. Final assembly and transfer of the production vehicles will take place at Rheinmetall Landsysteme GmbH in Kassel.

A proven success in multiple German states

While the procurement process moves forward at federal level, special ops units of the State Police of Berlin, North Rhine-Westphalia, Saxony and one other federal state as well as state law enforcement agencies in Austria all already deploy their own variants of the Survivor R. Its 4×4 MAN chassis, 340 metric horsepower engine, and high torque ensure excellent manoeuvrability, even in difficult terrain. The vehicle’s monocoque armoured steel cab, optional protective ventilation system, and other technical features provide superb protection from gunfire, bombs, and toxic gases. The extremely versatile Survivor R has already proven its mettle in numerous operations, protecting police officers on one occasion when a criminal suspect fired on their vehicle.

In late summer 2022, Rheinmetall hosted its first Survivor R User Day. This forum allows the company to collect information based on operational experience and incorporate this feedback into ongoing development of the product. Users reported back on their experience in using the Survivor R in day-to-day police operations and discussed various equipment configurations. The programme included test drives of variously configured Survivor R vehicles. The attendees were full of praise for the enhancements to the vehicle system, such as the new automatic transmission and other equipment features. They also had the chance to ask questions and discuss technical aspects with Rheinmetall employees from the Sales, Project, Development, Customer Service, and Service departments.

Action!

Of course, the users reserve the right to keep private such exclusive insights into how they use the Survivor R from day to day — whereas anyone can tune in and watch the Survivor R on TV.

“Alarm for Cobra 11: Unforgiving” – the plot

Semir Gerkhan (Erdogan Atalay) and Vicky Reisinger (Pia Stutzenstein) take on a criminal organization from Belgium that kidnaps people and tortures them in truck container prisons. The highway patrol detectives from “Alarm for Cobra 11” must work with the Belgian police to find out where the prisons are located. When the head of the criminal organization retaliates, Semir and Vicky get drawn into a war that has been going on for years between organized crime and the police in Belgium. “Unforgiving” premiered on 20 October 2022 on RTL+.

Technical data for the Survivor R (basic version)

Crew: Up to 11 people

Top speed: 100 km/h

Power: 250 kW (340 metric horsepower)

Torque: 1,250 Nm at 1,200–1,800 rpm

Emissions class: EURO 6

Drive configuration: Permanent four-wheel drive

Locking differentials: 3 x 100%

Chassis: MAN TGM 18.340

Maximum authorized mass: 17,000 kg

Available payload: 1,500 kg

Length: Approx. 6,860 mm

Width: Approx. 2,510 mm

Height: Approx. 3,250 mm

Optional equipment: Dozer blade, ladder, multipurpose turret system, weapon station, CBRN protective ventilation system

Impressions Survivor R

NATO refocuses: The Atlantic alliance has radically changed its policy toward Russia. At the core of the new strategy: defence, crisis prevention and security.

Image top: German Chancellor Olaf Scholz and President of Lithuania Gitanas Nauseda inspect the NATO EFP Battle Group in Rukla. The unit is led by the German armed forces. EFP stands for “Enhanced Forward Presence” and is intended to deter Russia. (Image: picture alliance/dpa | Michael Kappeler)

Reacting to changing geopolitical and strategic realities, NATO has adopted a new Strategic Concept in response to the Russian attack on Ukraine, a gross violation of international law. At its Madrid Summit, held on 29-30 June 2022, the western defence alliance made it clear that it would not stand idly by while Russia undermines the peaceful political order in Europe.

In the face of an increasingly fragile and unpredictable world order characterized political instability, strategic competition, and advancing authoritarianism, the Strategic Concept reaffirms “that NATO’s key purpose is to ensure our collective defence, based on a 360-degree approach.”

THREE KEY TASKS

In plain terms, this means that from now on the western alliance will focus on three core tasks: deterrence and defence; crisis prevention and management; and cooperative security. The western alliance also expressly acknowledges the commitment made in Article 5 of the North Atlantic Treaty, in which the mutual willingness of the 30 NATO member states to defend one another is enshrined: an attack against one state shall be considered an attack against them all.

The Strategic Concept begins with a clear analysis of the global threats facing NATO member states and notes with concern that peace in the Euro-Atlantic area has been shattered. There is a great deal of uncertainty concerning the political and strategic world order. The concept states: “We cannot discount the possibility of an attack against Allies’ sovereignty and territorial integrity.” Unlike before, the Russian Federation is no longer considered a partner, but “the most significant and direct threat to Allies’ security.”

International terrorism and conflict and instability in Africa and the Middle East are also classed as a threat and a challenge. The same is true of China, which in NATO’s view is deliberately remaining opaque about its strategy, intentions, and military build-up.

NATO, the North Atlantic Treaty Organization, was founded in 1949. It has been headquarted in Brussels since 1967. There are currently 30 states in the North Atlantic Treaty Organization, and Finland and Sweden are candidates for membership.

At the core of the new Strategic Concept are three traditional core tasks that aim to strengthen the entire western alliance and ensure it remains fit for the future:

Deterrence and defence. NATO’s deterrence and defence posture is based on a mix of nuclear, conventional, and missile defence capabilities, complemented by space and cyber capabilities. This posture is to be significantly strengthened to deny any potential adversary possible opportunities for aggression. Great importance is also assigned to maritime security, digital transformation, and the use of space and cyberspace.

Crisis prevention and management. The 30 heads of state or fovernment of the Atlantic Alliance have also pledged to increase their current efforts to better anticipate and prevent crises, wars, and conflicts. Crisis prevention is described as an important contribution to ensuring stability and security. Crisis management is also to be ramped up through closer cooperation with organizations such as the United Nations, the European Union, and the African Union.

Cooperative security. Because of this third core task, the Strategic Concept reaffirms an “Open Door policy” for all European democracies that share the values of the western alliance. The EU is described as a “unique and essential partner” for NATO. NATO and the EU play complementary and mutually reinforcing roles in supporting peace and security.

THE COURSE IS FIXED

Taken as a whole, the new Strategic Concept can be regarded as a course-setting interpretive document for security and defence policy in which NATO has set out its approach to counter future threats. With the political leadership in Moscow having lost trust and credibility in the eyes of the world as a result of the invasion of Ukraine, it is unavoidable that NATO and the EU will have to radically rethink their previous policies toward Russia, refocus and change course. It is not yet possible at this point to provide a reliable prognosis of what political changes and military power balances this will lead to for Europe in the long term.

The Russian invasion of Ukraine marked a turning point in history – and for the defence industry, too. Armin Papperger has been at the helm of Rheinmetall AG since 2013. In this interview, he discusses the Group’s evolving image, Germany’s ability to defend itself, his commitment to environmental sustainability – and how Rheinmetall is reconciling these imperatives.

Mr Papperger, on 27 February 2022, a Sunday, the Federal Chancellor proclaimed a historical ‘Zeitenwende’ (turning point) in a speech to the German Parliament. Where were you on that day?

I was at home, watching TV. I felt very tense about what would come, but basically knew what he would say. That’s why we were already well prepared at Rheinmetall and able to submit a so-called ‘potential list’ so quickly. It showed what we could supply at short notice – to the Bundeswehr, of course, but also to support Ukraine.

Were you surprised by the Russian invasion of Ukraine?

No, not really. You don’t order 150,000 troops to the border for no good reason. Once the troops were in place, there was basically no turning back for Putin. For me, it was clear from the outset that the attack would happen. What I didn’t foresee is that it would come from several directions at the same time.

The war in Ukraine isn’t just a regional conflict. Is what we’re seeing also a Russian attack on Western values?

Yes, that’s my impression.It’s obvious that Russia isn’t willing to support a rules-based world order. And in the long run, that’s the biggest problem: even if Putin is gone someday, we can’t assume that whatever government comes afterwards in Russia will necessarily mean a return to business as usual.

Which brings us to Rheinmetall and the defence sector. Do you get the feeling that the industry’s image has changed since the ‘Zeitenwende’?

Yes, I think that our image has changed for the better, but I don’t know if it’s going to last. In Germany, there are already clear signs of war weariness setting in, even though we’re not directly affected. I therefore worry that compassion and solidarity could soon evaporate, and with it, the will to look after our own security. That would be fatal.

How do things stand when it comes to making sure Germany can defend itself again? A lot of gaps need plugging at the Bundeswehr, both structural and material …

I think politicians genuinely want to whip the Bundeswehr back into shape. This is a process that will take at least five or six years. The 100-billion-euro package is a great opportunity for the Bundeswehr, but we can’t just let it be a flash in the pan. Achieving and maintaining NATO’s two percent goal over the long haul is more important…

… according to which member states are supposed to spend two percent of their gross domestic product on defence…

Right. Because we won’t be able to meet this goal if we order equipment for our armed forces and then probably can’t even afford to maintain it due to a lack of funds later.

What is Rheinmetall’s responsibility in these times?

We’re Germany’s biggest defence contractor, with something like 1,600 products in our portfolio. Rheinmetall is a vital part of the country’s national security architecture – and that also goes for our defence industry in general. Without this industry, Germany would lose political influence in Europe and beyond.

Back to policy. Do you think that Germany is doing enough to support Ukraine?

Ukraine needs an enormous amount of support at every level, to include reconstruction after the war. Whether we’ve reached the limits of what’s affordable in the meantime is not for me to judge. That’s something for politicians to decide on, and will require broad consensus, including in society at large.

Our European neighbours expect Germany to take on a leadership role. What do you think? Is Germany a reliable partner, especially in Central and Eastern Europe?

I know several heads of state there quite well because we’re present in these markets. They’re looking to Germany and definitely want us to take the lead as a nation. But this requires quick, efficient decision-making. Arguably Germany has room for improvement in this department.

What tactical and technical conclusions have you drawn from the war in Ukraine? The Russians have lost a tremendous amount of equipment, including thousands of tanks. Does the main battle tank have a future?

Sure, of course it does. Otherwise, our new Panther KF51 main battle tank wouldn’t have created such as stir or attracted so much attention when we recently presented it, and not just in defence circles. Today, the Panther has everything it needs, including more powerful main armament. Russian tanks like the T72 are practically defenceless against antitank missiles. This requires active protection of the kind Rheinmetall has developed. The Panther is protected from drones, too, thanks to our Top Attack Protection System. With countermeasures like these the main battle tank clearly has a future. Besides, it’s plain to see from the situation on the ground in Ukraine that tanks are still a tactical necessity.

Mr Papperger, as far as the media are concerned, you’re Germany’s top arms supplier. You’re also getting more political attention. How do you feel about this new role?

I would prefer peace. Personally, I would be happy to do without this role. At Rheinmetall, we have an obligation to society, an obligation we need to live up to. Our core mission is to supply the armed forces of Germany and its NATO partners with the best possible equipment.

In the meantime, more than 90 percent of your sales are to NATO countries and other friendly nations. But there are several customer countries that are always controversial. What do you think of the governing coalition’s efforts to tighten the regulations covering German arms exports?

We’ll certainly be able to supply our partner nations in future with no problem, first and foremost NATO and EU countries. It would be helpful to have a list of other approved countries, which would give us a clear basis for doing business. But here I see a fundamental problem: if every country makes its own rules, Europe won’t be able to grow together, and it makes industrial cooperation more difficult. Which is why I’d like to see a uniform European regulation for arms exports. As things stand today, German industry is at a major disadvantage. Our foreign competitors even cite being ‘German-free’ as a positive attribute in joint projects, because the lack of German participation makes it easier to market defence products internationally. This can’t go on.

Should Germany supply arms only to democracies?

That’s a political decision. Military cooperation is an instrument of foreign policy, and defence projects are part of it. Look, Germany tells Arab countries, “Please give us lots of your natural gas.” And here’s what they say: “Other countries were ahead of you. And unlike you, they help us out in other areas – for instance, when it comes to defence. Go to the end of the queue.” It really makes you think.

One country that you can’t sell military equipment to is China. But you have a strong civil sector presence there, with ten locations, primarily serving customers in the automobile industry. What potential risks do you see there for Rheinmetall?

I do indeed see certain risks in our civil operations, especially if the Chinese government insists on taking an even harder nationalist line. Most of our companies there are 50/50 joint ventures, with the Chinese government onboard. On the Executive Board, we keep a sharp eye on developments and make decisions accordingly.

Let’s get back to the historical ‘Zeitenwende’ for a moment. It’s a political expression, first and foremost, but your company has had to adapt to a dramatically altered situation. Is this a turning point for Rheinmetall too?

Yes, we’re now on a trajectory that’s bringing us significant growth – but also demanding a great deal of us. We’ve got to meet our customers’ requirements. To do this, we need to substantially increase our capacity. We’ve been gearing up production at our plants, moving to two or even three shifts. We’re boosting capital expenditure, too – even though we’ve already invested a lot. For example, we have new plants in Hungary, Australia and Great Britain. But we’re also considering increasing our capacity through new acquisitions.

Have new orders been coming in since the ‘Zeitenwende’?

Yes. The first major order was a contract for personal protection equipment for infantry worth almost 300 million euros. Now we’re on the verge of the second lot of Puma infantry fighting vehicles being ordered for the Bundeswehr, including retrofits of existing vehicles. Decisions are coming soon on a new 6×6 vehicle and a vehicle for airmobile operations. In addition, decisions on ammunition are on the way – in fact, we’ve already booked the first orders. We also expect to get a significant share of the digitization work currently in the pipeline. So, decisions worth several billion euros are currently pending.

It takes two years from the day a tank is ordered to the day it’s delivered. Why does it take so long?

The biggest problem right now is sourcing the necessary materials. If you order special steel for armour today, for example, it can take eight or even twelve months to arrive. Besides, tanks need tracks, guns, electronics… The delivery time for electronic components can be 24 months. In short, it can easily take a year and a half or even two years before a tank is ready to roll and qualified. On the other hand, assembling a tank goes relatively quickly.

Your defence business makes up an increasingly large share of Group sales. In view of this trend, what is your strategy?

For the foreseeable future, most of our business will certainly be in the military sector since this market is growing extremely quickly. I assume that around 80 percent of our business will be military-related by 2025.

But here’s something that’s very important to me: Rheinmetall is a technology enterprise and I want it to stay that way in future. We don’t want just to be a defence contractor. We’ve got terrific new technologies that extend well beyond the defence sphere – hydrogen technology, for instance. There are plenty of promising applications in the ‘warm home’ domain – by which I mean heating systems. We have new sensor technologies for the civil sector, too, and are developing a concept for an electric motor for a new hybrid military vehicle. My goal is to have our five divisions so thoroughly integrated that it’ll be almost impossible to tell the difference between our civil and military business. Moreover, we’re also considering whether we can use civil production facilities for producing military components in future. This is no trivial matter, because the security requirements in the military sphere tend to be especially strict.

You announced Rheinmetall’s transformation into a technology enterprise over two years ago. What concrete successes have resulted to date from closer cooperation between the two parts of the Group formerly known as Automotive and Defence?

We’re already making good headway. There are a whole bunch of examples. We have solutions in the field of automated driving and teleoperated driving. And we’ve got power electronics that we’re developing in Silicon Valley that can be used for military purposes. As I’ve already mentioned, we’re also developing high-performance electric motors for military applications. In the civil sector, we’ve teamed up with various cooperation partners to develop sensors that can detect a person’s condition, which can determine if somebody’s fit to drive. This has military potential, too, of course. We’re also pursuing this kind of cross-linking in air conditioner compressors and mobile fuel cell systems, but also in the realm of digitization and guarding against cyber threats.

In Hungary, we’re going to build a plant for capacitors that’s technologically unique. The components are necessary wherever a power storage unit is located between a battery and a motor. We have a patent in Europe and now plan to introduce these high-tech components together with our American partner throughout Europe, and potentially in Asia as well. This is an example of the technological leadership we’re seeking, with both military and civil applications.

The future looks bright for hydrogen technology. What does Rheinmetall’s strategy in this area look like?

I’m convinced there’s a megatrend moving in the direction of hydrogen as a climate-neutral energy source. Four years ago, we started doing in-depth research into hydrogen. I think hydrogen-based drives for mobility will play a significant role, especially for trucks. We know that the biggest challenge in establishing a global hydrogen economy is having to produce large amounts of green hydrogen as cheaply as possible. And that’s exactly what our project E²NGEL aims to do: we’re developing electrodes for alkaline electrolysis that don’t contain precious metals and work really well, thus helping to cut the cost of producing green hydrogen.

Whether it’s with solar panels, wind or waterpower: we’re going to be able to use renewable energy to produce green hydrogen. In South Africa, we’ve just presented a turnkey, mobile, modular solution that can generate, store and transport green hydrogen that’s CO2-free. We can set up four containers and sustainably supply 30 or 40 households with climate-neutral energy, pretty much anywhere. As you can imagine, a capability like this would also be very useful during deployed military operations.

So, you’re already offering a complete system solution?

Yes. But our technologies are also present in various other components. In the government-backed LORICA project, for example, we’re working on an innovative pressure tank system for hydrogen that will be able to store hydrogen on ships, trucks, buses, trains and cars. We’re also making a decisive technological contribution when it comes to transporting and trans-shipping hydrogen.

In the fuel cell systems domain, we’re cooperating with well-known partners like Ballard and Cellcentric to make fuel cell systems more efficient, less expensive and durable thanks to components like our hydrogen recirculation blower.

As one of the world’s top pump manufacturers, we’re predestined to play a major role in the hydrogen world: our electric coolant pumps can already be used in fuel cell systems today. We’re also one of the world’s biggest valve makers, which lets us offer products that are vital for the safe operation of fuel cells.

Finally, we also happen to be specialists in the field of thermal management, which is very important in fuel cells. As you can see, we’ve made a major commitment here – and we’re well positioned to take advantage of this now. Things look very promising.

So, the civil use of technology continues to play a role for you?

Absolutely. For me, ultimately it doesn’t really matter if the task at hand is civil or military. I like technology and I like our people. I want the men and women who work for Rheinmetall to have decent jobs that are as secure as possible. Our defence business is experiencing a boom now, which helps us all – and that goes for both the military and civil side of the house at Rheinmetall.

You expect your military business to grow by well over 10 percent a year. How do you plan to square this increase in output with Rheinmetall’s sustainability goals? After all, you want to be CO2 neutral by 2035 …

We’re already doing a lot in this area. Year in, year out, we’ve been investing eight-figure amounts in sustainability. Our priority at Rheinmetall is obviously to cut our CO2 emissions. We can’t be completely CO2-free, but we can compensate for the greenhouse gases we emit. How do we do this? In South Africa, we’re building a big solar field where we’re going to generate electricity for producing green hydrogen, which we also want to make available to other users.

Most electricity in South Africa is generated in coal-fired power plants…

True – there’s an urgent requirement for action there. But a lot can be done. As I’ve already pointed out, we’re counting on hydrogen technology in South Africa. Using leftover electricity, we want to produce green hydrogen, which will mean that our five factories in South Africa can operate quasi-CO2 free. We’re switching from coal as an energy source to hydroelectricity and solar power. And South Africa’s just one example among many.

Let’s have a look at Germany: at your Unterlüss plant in the Südheide, there’s currently a big hole in the ground. Are you building there for a CO2-free future?

Yes, that’s the site of our new woodchip powerplant. Unterlüss is our biggest plant in Germany, with over 2,000 employees. We have a lot of land – 54 square kilometres, to be exact – much of it wooded. In future, we’re going to turn dead wood and branches that would normally just rot away on the forest floor into woodchips. The thermal energy produced by the powerplant will supply the entire plant, including the production of tanks, guns and ammunition.

Do you have a clear idea of Rheinmetall’s total CO2 footprint?

Yes, of course. We collect data from all over the Group, so we know what our monthly CO2 emissions are and what energy sources produced them. This lets us work out ways of saving energy and switching to renewable sources. In the medium term, I don’t just want to pay for green electricity – if we did that, we’d still be electricity consumers. I want us to be energy producers in the medium term – that would be a real contribution to sustainability. We’re looking into setting up our own wind farm, by the way. We need to find a suitable location. To meet Rheinmetall’s energy needs in Germany, we’d need around 16 wind turbines with an output of 4 megawatts each. This would mean an investment in the three-digit million-euro range, which we would of course have to do gradually. But over the course of several years, it’s definitely doable and a project near and dear to my heart. This way, we could be completely CO2-free, rather than just CO2-neutral thanks to offsets. That would be worth almost any effort!

Mr Papperger, you’ve been at the helm of Rheinmetall for nearly a decade now. As you see it, which of your decisions during this period have done the most to shape the company’s destiny?

I think the most important thing I’ve done is picking the right people. A company’s success depends on teamwork. This means having loyal staff, including in key executive positions, of course. We have highly motivated people, who are totally dedicated to Rheinmetall and its mission. For me, that’s the most important thing. I’d like to express my thanks to everyone who works hard for Rheinmetall. I’m especially grateful to my long-serving companion Helmut Merch, who for the past ten years has performed a great service to the Group as CFO. He will be taking his well-deserved retirement at the end of the year after a 40-year tenure at Rheinmetall.

Another important decision was eliminating the artificial demarcation between Defence and Automotive. We’ve succeeded in turning Automotive into an organization capable of exploiting opportunities in other important growth sectors such as hydrogen technology. This means that we’re entering a new epoch in very good shape – an epoch of robust growth, by the way. We’ll be growing by between 10 and 20 percent a year, which means we’ll need a very stable, highly motivated team. I’m happy to say that that’s exactly what we have.

And this team needs reinforcements. Anybody who’s looking for a challenge should contact us at Rheinmetall! We’ve got lots to do and are looking for good, loyal people. Success is sexy, as I like to say, and Rheinmetall has plenty to offer these days, with secure jobs and excellent opportunities for personal development in Germany and around the globe.

ARMIN PAPPERGER

Born in 1963, Armin Papperger has been Chief Executive Officer of Rheinmetall AG since 1 January 2013. At the same time, he is responsible for the Defence sector as Chairman of the Corporate Boards. After graduating with a degree in engineering, he began his career in quality management in the Defence sector of the Rheinmetall Group in 1990. Having held a number of further posts in this area, he became Managing Director of various subsidiaries of the Defence sector in 2001. In July 2007, he was appointed head of the Weapon and Ammunition business unit. At the beginning of 2010, Papperger assumed responsibility for the Vehicle Systems and Weapon and Ammunition business units on the Defence Corporate Board. He has been a member of the Executive Board of Rheinmetall AG since 1 January 2012.

Russia’s attack on Ukraine challenges Europe and the world. For Germany, the EU and NATO, the invasion represents a profound turning point – and with it, serious changes in security policy.

Russia’s attack on Ukraine on 24 February 2022 will surely figure prominently in the history books. For the Russian invasion was not merely a flagrant violation of international law; it has also triggered a far-reaching process of change in Europe, whose political, economic, and military consequences it is too early to evaluate in full.

NATO General Secretary Jens Stoltenberg was not exaggerating when, deeply worried, he stated that the war in Ukraine had sparked the “biggest security crisis in Europe since the Second World War”.

To be sure, however, the war in Ukraine is not the sole cause of these geopolitical transformations. On the contrary, a whole host of very different and partly diverging developments are influencing Europe’s future and will continue to do so. Here is a brief overview.

USA AND NATO

In coming years, close transatlantic ties to the United States and membership in NATO will continue to be Europe’s – and especially Germany’s – basic life insurance policy. Yet Europe is no longer a top US foreign and defence policy priority. The fast-growing nations of the Pacific Rim and their strategic military significance in the Indo-Pacific region have for years played an increasingly important role in Washington’s geopolitical and economic calculations. The creation in 2021 of the trilateral AUKUS alliance between Australia, the United Kingdom and the United States is just one example of this trend.

RUSSIA

Owing to its offensive war against Ukraine, the regime in Moscow is no longer viewed in the West as a valued strategic partner, but instead is now vilified as its greatest threat. The previous credo of German governments that security could only be achieved in concert with Russia rather than by opposing it, has proved to be political miscalculation. As Chancellor Olaf Scholz stated in a government declaration on 22 June: “For the foreseeable future, a partnership with Russia of the kind still envisaged in 2010 as a strategic concept is inconceivable with Putin’s aggressive, imperialist Russia.” In plain language, this means that Germany must now rethink and recalibrate its previous Russia policy.

CHINA

The People’s Republic of China has long since ceased to be a “sleeping giant”, but instead seems to be pursuing its political goals with a clear strategy. Only gradually has the realization dawned on the West that China, while not posing a direct military threat due to geographical distance, has become a systematic competitor, engaging as discretely as possible in a consistent policy of expansion. China is therefore America’s top foreign and defence policy priority. President Joe Biden has gone so far as to speak of a global struggle between the democracies and the autocracies. And indeed, China’s ambitious “Silk Road” project, though ostensibly motivated by economic and technological considerations, is driven even more by ideology and power politics.

TAIWAN

The conflict over Taiwan is a textbook example of just how strongly ideology, power dynamics and history dominate China’s foreign and defence policy. China’s position is clear: Taiwan is and remains a province that historically belongs to the People’s Republic. Equally clear is America’s policy of strategic ambiguity, which consciously leaves open the question of how the United States would react to a Chinese attack on Taiwan. If the conflict now being stirred up by China through military threats and attempts at intimidation were to escalate into a war because of an offensive military manoeuvre, this would not only have a massive negative impact on the security of the nations of the Indo-Pacific region. It would also lead to massive disruption of global supply chains, especially since Taiwan’s IT industry produces basic systems and components for Europe’s high-tech industry.

EUROPE

The EU and NATO play a complementary and mutually reinforcing role in maintaining peace, security, and stability. But in order to overcome Europe’s longstanding historic dependence on the US and to assert its own (security) interests vis-à-vis the US, Europe must do more for its own strategic sovereignty and thus for its own defence. This is even more valid given that future political developments in American harbour uncertainties and risks for the continuity of US foreign and defence policy.

Germany’s former foreign minister, Sigmar Gabriel, repeatedly pointed out that Europe should do more for its own defence, because in a world of meat-eaters, vegetarians would have a hard time surviving. And it was none other than Jean-Claude Juncker, the long-serving President of the European Commission, who made it plain that Europe finally had to develop a “global policy capability” and, owing to its immense economic and technological potential, to enter the world stage as a stronger political actor. The efforts by many European nations to meet the NATO goal agreed in 2014 of spending two percent of gross national product (GDP) on defence reflect this development.

Sweden and Finland joining NATO

Prompted by the Russian invasion of Ukraine and concerns for their national security, these two Sweden and Finland applied to join NATO in summer 2022. Sweden, a byword for political neutrality for over 200 years, and Finland, which shares a roughly 1,300 km-long border with Russia, will – presuming the accession protocol is ratified by every NATO state – increase the number of NATO member nations from 30 to 32, as well as substantially strengthening the Atlantic alliance’s northern flank.

EUROPE (ALMOST) WITHOUT BORDERS (Interactive)

Ukraine and Moldova to join the EU

The European Union unanimously acknowledged Ukraine and Moldova’s status as candidate countries with 27 ‘yes’ votes on 23 June 2022. Once all the criteria are met, the accession of the two countries into the EU community of nations would bind them more closely to Europe. Thus, in a few years’ time, the EU could have 29 members, up from its current 27.

New alliances with Russia

The planned expansion of NATO and the EU are naturally a thorn in the side of the political leadership in Moscow. It is there no coincidence that President Vladimir Putin’s first trip abroad since the invasion of Ukraine was to Central Asia in June 2022. He described five states (Kazakhstan, Kirgizstan, Tajikistan, Turkmenistan and Uzbekistan) as “historically Russian”. Furthermore, at a summit meeting of nations bordering the Caspian Sea (Azerbaijan, Iran, Kazakhstan, Turkmenistan and Russia), Putin evidently weighed the possibility of new alliances. Still difficult to assess are Russia’s attempts for a rapprochement with China, which has been notably reserved in its criticism of the Russian attack on Ukraine.

Russian rocket systems in Belarus

In a visit to St. Petersburg in June, Putin announced that Russia would be stationing Iskander-M missile systems in Belarus in coming months. These mobile launchers can fire short-range systems as well as cruise missiles, tipped with conventional or nuclear warheads. If the systems are stationed as planned, it would pose a new threat to Europe, especially to the frontline NATO nations Poland, Lithuania and Lativia, all of which share a border with Belarus.

Something new – national security strategy

In his “Zeitenwende” (turning point) speech on 27 February, Chancellor Olaf Scholz announced a special €100 billion fund and an initiative to whip the Bundeswehr back into shape as Germany’s immediate responses to Russia’s unjustified offensive war against Ukraine.

In addition, under the auspices of the German Foreign Ministry, a security policy white paper is currently being drawn up with the aim of defining a national security strategy for Germany. This is something new. Germany has never had a national security strategy before.

The profound geopolitical changes that have taken place in recent decades, e.g., the reunification of Germany, the collapse of the Warsaw Pact and the senseless war in Ukraine, make this strategy a crucial necessity. Forming the basis for this is, among other things, a clear expansion of the meaning of “security”. This is no longer confined to external, i.e., military security, but now extends to internal and socio-economic security, as well as cyber, energy, food, raw material and supply chain security.

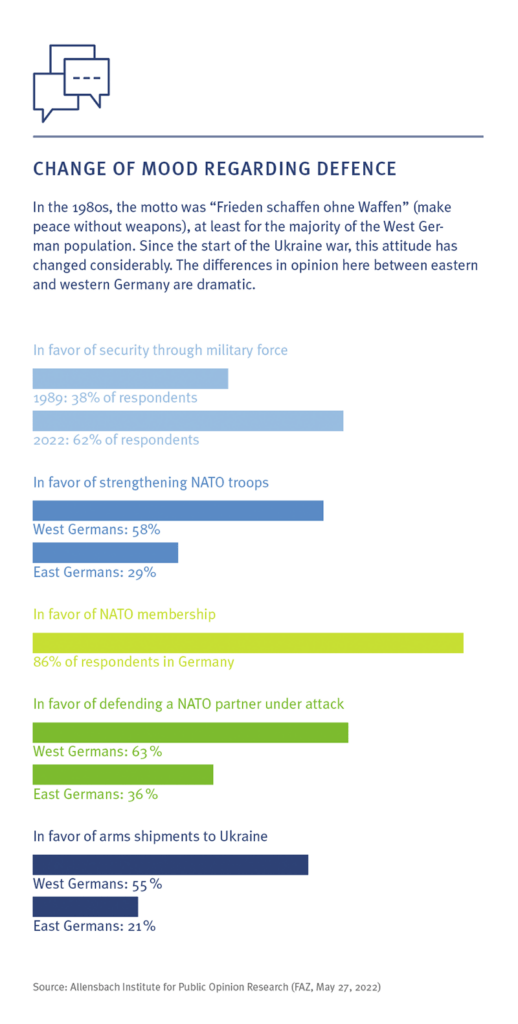

It comes as no surprise, then, that this multifaceted development is also affecting public opinion. A significant change in German attitudes concerning the sensitive issues of defence and security policy is apparently underway. For instance, the majority now strongly approves of achieving security through military strength as well as Germany’s continued membership of NATO and the controversial supply of weapons to Ukraine.

Whipping the Bundeswehr back into shape

The special fund for the Bundeswehr announced by the German government, coupled with a substantial increase in the investment portion of the defence budget, will make it possible to reequip the German armed forces, enabling them to carry out their core mission of defending Germany and its NATO partners again. By 2025, every active soldier is to be kitted out with completely new battle dress uniforms and protective gear – this, at least, is the current Bundeswehr plan. The resources are also intended to turn the Bundeswehr into a European force multiplier in NATO and the EU. The special fund will be used to bridge capability gaps resulting from years of spending cuts.

The economic plan associated with the special fund offers a good overview of the planned expenditure, which is divided into four dimensions:

The Air Dimension: The largest share of investment (€33.4 billion) is earmarked for the “Air Dimension”, with the Air Force, Army, and Navy all benefitting. The procurement programmes include, among other things, 35 American-made F-35 multirole combat aircraft, 15 Eurofighter Electronic Combat Role (ECR) jets, and sixty Chinook CH-47F heavy transport helicopters.

The Command & Control / Digitization Dimension: The second largest share of investment (€20.7 billion) is intended to improve Germany’s command and control capabilities and push ahead with digitization. In particular, the procurement of advanced radio technology will enable German troops to communicate with their NATO comrades via encrypted wireless links.

The Land Dimension: Around €16.6 billion has been set aside for the “Land Dimension”. Planned investments include, among other things, retrofitted Puma infantry fighting vehicles and successors for the Marder and Fuchs/Fox systems. Part of the resources will go on the development of a new German-French main battle tank, the Main Ground Combat System, or MGCS.

The Naval Dimension: This dimension is due to receive €8.8 billion, encompassing, for example, the K130 corvette, the F-126 frigate and the 212 CD submarine, which is currently under development.

Securing Germany’s long-term future

At present, it is still not clear if Ukraine will be able to withstand Russia’s military preponderance over the long haul. It would be desirable and sensible if diplomatic channels were to remain open, enabling the difficult work of trying to find a viable political solution to end the war in Ukraine through diplomacy and dialogue to continue.

Moreover, the changes in the megatrends outlined here show that policymakers need to rely more strongly on credible military force again. Security isn’t something that can be taken for granted, nor can it be achieved without striving to achieve an independent defence capability.

For these reasons, the planned defence expenditure should be understood as a strategic investment in security, thus making a material contribution to securing Germany’s future. This is absolutely vital. For the radical transformation of Europe’s security architecture is already well underway.

Humanity is facing immense challenges. Overcoming them requires us – governments, companies, and people – to all pull together. What was once considered “nice to have” is now a vital factor in determining a company’s long-term business success. Sustainability is now a “must have” – including at Rheinmetall.

(image: istockphoto/ Joey Ingelhart / image top: FOJANA Unterlüß)

Sustainable clothing, sustainable food, sustainable travel – seldom has a term taken off so fast. And rightly so, because one look at the news will tell you that we’re not just facing one crisis; there are several, and they all require our attention at the same time. This means we have a phenomenal amount of work to do. Robert Swan, the famous polar explorer and environmental activist, made this point so succinctly when he said: ‘The greatest threat to our planet is the belief that someone else will save it.’ “We all have a collective duty here,” notes Ursula Pohen. She heads Rheinmetall’s Corporate Social Responsibility department, under whose remit all the threads of sustainability come together. “Sustainability is not folklore, it’s not for ‘do-gooders’; sustainability is an important part of our business.”

Passionate to be part of the solution

For some time now, customers, investors, employees and the public have not just been interested in the hard financials. They are seeking to form a complete picture of how companies operate, how they conduct their global business activities, and the impact these have on people and the environment. ESG – Environmental, Social, Governance: These are the three buzzwords by which companies will have to be measured in the future.

“Our stakeholders expect us to take responsibility as a company. We’ve been accepting this responsibility for over 130 years. For us, responsibility means doing our bit to help resolve the most pressing problems of our time, the most pressing of which is mitigating the effects of climate change,” declares Armin Papperger, CEO of Rheinmetall AG. “We’re not doing this just because we have to. We’re doing it because we want to! Passion for technology, passion for sustainability – we believe in both.”

Ambitious goals for sustainable development

Making a commitment to sustainability means having to formulate a sustainability strategy and setting goals. This applies equally to all three areas for action: environment, social, and governance. Three categories with one aim: obtaining a complete picture of sustainability in all its facets. Sustainability has been on everyone’s lips since 2015 at the latest. It was then that the global community adopted 17 sustainable development goals with its 2030 Agenda. World leaders also agreed under the Paris Climate Agreement to limit global warming to well below two degrees centigrade, prompting the corporate sector to make considerable efforts.

The way to carbon neutrality

The Group is making good headway on the environment front. Rheinmetall has set itself the goal of becoming carbon-neutral by 2035. To make sure the company is making tangible progress, it has drawn up a road map. “We are holding ourselves to clear, scientifically proven standards as we move to improve our energy and climate footprint,” explains Dr Alexander Vogt, who heads the Group’s Energy Management department.

The department is now preparing the Group to join the Science-Based Targets initiative, or SBTi for short. Over 3,000 companies belong to this international network. Its science-based targets will help to limit global warming to 1.5°C. “For Rheinmetall, this means cutting all the direct and indirect emissions from our business activities by 4.2 percent a year,” explains Dr Vogt. “It also means formulating clear reduction targets for greenhouse gas emissions throughout our entire value-added chain.”

Several pilot projects are currently in progress, including an energy supply project at Rheinmetall’s Unterlüss site. Due to go into operation in 2023, a new heating plant there will be powered by material from the company’s own forestry operation, including wood pellets. This will save 5,200 tons of CO2 emissions a year. Further heating systems are planned in Unterlüss to reduce the plant’s greenhouse gas emissions and make production less dependent on fossil fuels and the current limited availability of these fuels.

Thinking about climate protection on a global scale

“We’re taking a three-pronged approach: we’re saving energy, we’re making ourselves more independent and we’re obtaining more power from renewable sources,” states Dr Vogt. One example of this can be seen in South Africa, home to Rheinmetall Denel Munition. The country gets most of its energy from coal. “We’re working with a local partner there to build a photovoltaic system so that we can supply ourselves with renewable energy.” The Group is currently exploring 20 larger-scale projects in all its divisions, with another 30 under development. Because Rheinmetall thinks globally when it comes to protecting the climate, the Group is also looking into procuring green energy for all its locations worldwide.

Sustainability is not an end in itself

Thus far, the strong focus on climate and environmental issues has somewhat overshadowed the social aspect of sustainability. “That’s now set to change – driven not least by the increasing regulatory requirements at national and international level. Due diligence requirements on human rights, in the company itself and the wider supply chain, are increasingly important,” notes Ursula Pohen. The third pillar of ESG comprises governance, compliance, risk management, and internal control systems. “If you like”, she adds, “the ‘G’ for governance includes all the work that ensures we comply with the rules and regulations.”

The green transformation of a globe-spanning Group like Rheinmetall involves far-reaching change and affects a whole host of administrative, operating and strategic processes. One thing’s for sure: sustainability is not an end in itself; it’s about an organization’s ability to continue creating value in the future – a task that’s never complete.

Exchanging knowledge, engaging in conversation, sharing advice – Rheinmetall employees can do all this in the Women@Rheinmetall network. Connections cultivated in this forum can have a positive impact on their entire professional lives.

“This industry is simply fascinating,” says Monica Wertheim, “it revolves around human mobility and security – two topics that I can totally identify with.” As head of Rheinmetall’s Global Talent Acquisition & Employer Branding department, her job is to recruit specialists and executives for the company, striving to keep the number of women as high as possible. Only a small percentage of female graduates opt to study STEM subjects (science, technology, engineering, and mathematics), and most jobs at Rheinmetall are in traditionally male-dominated areas.

Legal quotas play a minor part in the company’s motivations. The greater the percentage of women, runs the argument, the better it is for the company. Studies show that the proportion of women in management positions is one of the factors that determines the success of a business. And Monica Wertheim wants to share her fascination for the industry – and not just with prospective applicants, but with the female employees who are already part of the Group. In Monica Wertheim’s book, recruitment isn’t just about hiring, but ensuring that employees remain at the company.

A network for women

When Monica Wertheim, a Uruguayan national, joined Rheinmetall in 2017, she recognized right away what female employees at Rheinmetall needed: a sounding board – and so Women@Rheinmetall was born. It’s a forum that promotes the transfer of expertise, where women can exchange ideas and consult one another. The network comprised barely a dozen women to start with. Now there are over 600, something Monica Wertheim is proud of: “They come from every location, all rungs of the hierarchy, all age brackets. In a way, they are the face of Rheinmetall’s diversity.” The connections made here and the presence of female role models in the company have the power to shape one’s entire career.

WOMEN@RHEINMETALL

Monica Wertheim founded the network shortly after joining Rheinmetall. Almost 600 female employees from 19 countries are now involved. The aim of Women@ Rheinmetall is to promote and support the professional development of women at every echelon of the Group.

Outside the Women@Rheinmetall network, the Rheinmetall Academy in Germany engages in the targeted advancement of women. It offers management development programmes and training sessions specifically for women.

Many small steps

But all efforts, networks, and empowerment actions are of no avail if the corporate culture does not live up to its promise. Rheinmetall employees should have a workplace where they feel safe, a workplace that champions their talents, a workplace they can relate to. This should apply to the staff, insists Wertheim, irrespective of age, gender, or skin colour. This is because she doesn’t want to see herself as a special officer for women: “Rheinmetall is an excellent employer, period – not just for women!” She is also critical of the quota: “Personally, I don’t think it’s appropriate.” Support, building trust, and mentoring are much more important criteria in her opinion – in other words, everything that Women@Rheinmetall has to offer. “Every woman in the network makes the whole construct stronger,” says Monica Wertheim.

Recruitment may well be a big challenge, but the intensive work of convincing women is progressing in baby steps. The proportion of female trainees is now relatively high at just under 30 percent. This means the company will take even bigger steps going forward.

MONICA WERTHEIM

A graduate in Economics, Monica Wertheim has been Senior Vice Preseident of Recruiting and Employer Brand Services at Rheinmetall AG since March 2017. She previously worked in similar positions at E.ON/Uniper and in marketing and sales at the Kleffmann Group and Muskator Werke.

In Hamburg’s Ottensen borough, a new mixed-use district featuring rental flats, condominiums, and commercial space is taking shape on and around a factory site that is steeped in history.

The site was once home to a large piston factory that lay at the heart of this bustling north German port city. Going back almost one hundred years, the factory produced pistons for aircraft, ships and cars. But fierce competition from other piston manufacturers worldwide made it difficult for the factory to continue, and, after a long struggle, it was finally forced to discontinue operations. Many workers lost their jobs, and there was an outcry throughout the city.

By 2009, what started off as a sad tale was a painful reality for all involved. But the story of the flourishing redevelopment of the former piston factory is the closest thing you will hear to a fairy tale – and one that literally came true. But let’s tell the story in the right order and not get ahead of ourselves.

A site encompassing 35,000 square metres – that’s roughly five times the size of the footfall pitch in Hamburg’s Volksparkstadion – couldn’t just go unused or be left to become derelict. The initial idea was to find an interim use for the site while a new development plan was drawn up for the district. Everyone knew beforehand that this would be years in the making. The plan was to breathe life into the site without hampering necessary construction measures. The vibrant diversity this created would come to characterize the site’s further development and use.

Resourceful tradespeople were the first to discover the potential of this industrial wasteland with its stylish brick buildings, which once formed the backdrop of an Evelyn Hamann crime scene. In short order, part of the area along Hamburg’s Friedensallee was transformed into a thriving business location, which in the years that followed served repeatedly as a cool setting for numerous cultural events. The reasonable rents attracted not just small workshops and trade businesses but also members of the arts and culture community to come and settle there. The concept took off, and a “Kolbenhöfe e.V.” association was established to represent the interests of the new tenants, which later went on to become a cooperative.

An extensive clean-up operation

Use as an industrial premises for nearly 80 years inevitably left its mark, due not least to the presense of a foundry on the site. Once the site had been inspected by independent experts, an extensive clean-up was required, which initially involved tearing down parts of the halls. During the clean-up operation, which was approved by the Hamburg government agency for environment and energy, the contaminated earth was removed and replaced with fresh soil. This literally prepared the ground for a healthy new living and working environment.

Intensive public participation

But that wasn’t enough. he planning process for the site and surrounding district first had to ensure that the outcome would meet the needs not only of the city, but also its residents, and be commercially viable at the same time. A regulation in Hamburg prescribes that 30 percent of new residential developments must consist of social housing.

“From the outset, we insisted on an intensive public-participation process for development and design of the new district. After all, to succeed in the long term, a development project has to proceed in close cooperation with the city district,” says Holger Gradzielski, managing director of Rheinmetall Immobilien GmbH (RIG), which owns the former factory site in the Altona borough. “But”, Gradzielski is quick to add, “the solution has to be commercially viable as well!”

In 2013 the “Dialogwerkstatt Friedensallee” was founded. This “dialogue workshop” not only allowed residents to look at the potential plans but also let them contribute their own ideas to the planning process. Regional representatives of the Altona borough were also involved in the launch of an urban design competition, with ten architecture firms taking part. The areas were to be divided equally between living spaces and business spaces.

The designs were evaluated by a jury, with the public included in the whole process at every turn in a transparent workshop, not to mention special information points detailing the development planning process. The competition yielded a successful blend of existing structures with the new residential buildings, which are connected by courtyard areas. Anyone who is interested can look up the development and find out how building is progressing by going to www.kolbenhoefe.de, which is still active, in addition to a live webcam.

The fairy tale continues

Finally, in 2018, the official planning phase of the Ottensen development plan was practically complete. The plan included a property owned by Henkel through its subsidiary Schwarzkopf, which is directly adjacent to the Kolbenhöfe site. In the same year, RIG, which had meanwhile embarked on a joint venture with Otto Wulff Projektentwicklung GmbH, was able to acquire, develop, and build on this additional 46,000 square metres of land. Another player involved in the project is the Altona savings and building association (altoba), which had previously acquired two building sites totalling 13,000 square metres on the Kolbenhöfe site and is responsible for planning and building social housing there.

he expansion marked the birth of Kolbenhöfe II. This was a unique opportunity for RIG, as Gradzielski explains: “Both plots are part of the Ottensen development plan, and they went through the planning process together. This meant we were aware of the specifics of the new space, which simplified development of the entire area for us to a significant extent.”

As the area of the Kolbenhöfe district increased, so too did the number of flats, which grew to around 680, with roughly 200 of these earmarked for social housing. And because a proper neighbourhood needs a space where things like a weekly market can be held, the Kolbenhöfe district also has a prominent local square.

Vibrant diversity proves a marketing success

Good ideas spread quickly, and Kolbenhöfe is no different. Besides the already renovated Hall 7, RIG has succeeded in reselling some of the residential buildings, which are still under construction. The buyer is purchasing 163 completed rental flats, 26 of which are social housing, and 6 commercial units.

Another prominent buyer is the Hamburger Konservatorium music conservatory, which is establishing its new premises at Kolbenhöfe. This longstanding centre of musical learning will move into a converted former warehouse building, which it will use as a music school and academy, complete with rehearsal and seminar rooms. A new concert hall is also being built, which will be structurally connected to the warehouse building. A musical day-care centre will also liven things up in this blend of historical and new buildings, the hallmark of a vibrant and diverse district development.

Within the walls of the Konservatorium’s music school and academy and at its many other sociocultural initiatives, 11,000 pupils, 300 students, and 240 lecturers will play music in spaces that once beat to the rhythm of casting machinery.

Solid ground

What about the craftspeople and tradespeople? They have invested in Kolbenhöfe as well, jointly purchasing their hall through their own cooperative, the Genossenschaft Kolbenwerk eG, with the help and support of RIG, which has tailored the building to meet the individual needs of the new owners, bringing it up to the latest technical standards. Nearly thirty small businesses operate there now, including a vintage car workshop, a motorcycle self-help store, a metalsmith, a joinery, a surfboard builder’s shop, as well as media and creative businesses. Roughly 100 people work in this building. The new owners are unanimously pleased to be able to keep working on solid ground in the extensively renovated halls and rooms. Given their shared history, this is an especially happy development, and we hope that they all live happily ever after.

Central location

The Kolbenhöfe site, which covers 8.5 hectares in Hamburg’s Ottensen borough, is one of many individual projects forming the central core of the future district at Friedensallee, which will house a total of 1,200 new apartments, of which around 400 will be social housing. The area also encompasses space for small businesses, a day-care centre, and offices for upwards of 1,500 workers – not to mention the thirty or so workshops in the former factory hall, which has been renovated from the ground up.

Large-scale bushings for gearboxes destined for wind turbines all over the world are being produced in Papenburg, Germany, using a machining technology that is unrivalled in Europe. An important contribution to sustainable energy generation and reducing humanity’s carbon footprint.

(Images: ©Ralf Grothe, zeit-licht.de 2022)

The cast blanks for these bushings are made at Europe’s largest continuous-casting plant for non-ferrous metals. Rheinmetall operates this facility at the Papenburg plant. The specialists in Papenburg use aluminium bronze for the bushings, which are approximately 60 centimetres long, have a diameter of 44 centimetres and weigh around 105 kilograms.

This material features exceptionally high strength, thanks not least to a high percentage of copper. It is also very corrosion-resistant, making it suitable for use in various climate zones – even in the harshest environmental conditions. Each wind turbine has three large bushings and five small ones, along with twelve thrust washers; different versions of this configuration also exist.

A WIDE RANGE OF APPLICATIONS

The environmentally friendly task of the gearbox is to convert the relatively slow speed of the wind turbine blades into a very high rotational speed in the attached generator to produce power. Modern offshore wind turbines can generate up to 15 megawatts of power.

(Images: ©Ralf Grothe, zeit-licht.de 2022)

The bushings for the wind turbine gearboxes are machined using a complex method that gives them their spherical shape. But before production of the first series could start in November 2021, the Papenburg facility had to be equipped with a state-of-the-art machining centre costing nearly €2 million. An air-conditioned room was needed so that the bushings could be machined at a constant ambient temperature. Extremely low tolerances in the mm range make maintaining a constant room temperature of 20 °C (+/- 1 °C) vital. Even the temperature of the cooling water in the machine tool is controlled.

The same high-precision approach continues in the number of residual particles permitted. After machining, each workpiece is checked individually and then again following a special final cleaning procedure in the laboratory.