155mm in the spotlight

4. November 2025

What do a Soviet space capsule, a Japanese auxiliary heater, and an American fuel cell truck have in common with a Polish record player? The answer to this seemingly difficult question is that all of them might

contain electric motors from the Rheinmetall plant in Hartha.

Rheinmetall Power Systems

Founded in 1922, the plant in Hartha has been part of the current Power Systems division of Rheinmetall AG since 1992.

Business fields

The plant in Hartha develops and produces electric pumps and motors in various performance ranges, and for different tasks in vehicle technology and beyond. In addition, the focus is on new technologies in the fields of mobility, digitalisation, home automation, and energy.

Staff

360

51 developers, 8 apprenticeships, 6 dual students in the Bachelor’s degree programme “Digital Engineering”.

FROM A FORMER STATE-OWNED ENTERPRISE TO AN INTERNATIONALLY SOUGHT-AFTER AUTOMOTIVE SUPPLIER

EUR

240

million have been invested by Rheinmetall in modernising the site since taking over the plant in Hartha, Saxony.

For over 100 years, electric motors have been manufactured in the small Saxon town of Hartha, which has a population of just 7,000. Over the past century, the company has built up extensive experience in the development and manufacture of all types and sizes of electric motors, which are used in a wide variety of products and industries. In addition to its technologies for combustion engines, the plant is therefore also at the cutting edge of electromobility. But not only there!

An example of German history

At the same time, the history of this traditional location in the triangle between Chemnitz, Dresden, and Leipzig reflects German history. Founded in the economically turbulent year of 1922, the plant’s product portfolio had already been affected by World War II, and its conversion into a state-owned enterprise in former East Germany did the rest. Hartha quickly became one of the most important and largest electric

motor manufacturers east of the river Elbe. With up to 3,200 employees at nine production sites, ELMO – then known as VEB Elektromotorenwerk Hartha Sachsen – also supplied the former Eastern Bloc with electric motors. This period also saw the emergence of a special defence technology facet of the site, which at the time carried out orders for the East German Army under the utmost secrecy, and even manufactured electric motors for the Soviet space programme, which were used to adjust cameras in space capsules and satellites.

Wide range of products

The list of innovations and components “Made in Hartha” is tremendous. To mention just a few: since the 1990s, the portfolio ranges from vacuum pumps and motors for electric fuel pumps to plastic suction pipes, electronic throttle controls, drives for truck exhaust gas recirculation systems, and secondary air pumps to the latest water circulation and coolant pumps. These are complemented by products for electromobility and new drive systems, such as a hydrogen recirculation blower for fuel cells

and an extremely powerful 2,000-watt electric coolant pump.

RISING FROM THE ASHES LIKE A PHOENIX

The site, which was literally lying on the ground after the fall of the Berlin Wall, has developed continuously since its takeover by the Rheinmetall group in mid-1992. The Rheinmetall subsidiary Pierburg invested heavily in renovating buildings in need of refurbishment and replaced the machinery. “We are proud of the growth and seamless integration into our corporate group that has developed under the changing management teams” says Mario Schäfer, who has been managing the Saxony plant since 2017. For the production specialist, the integration of his site into the corporation’s development activities is particularly important. “With our trained team on site and in cooperation with our central development department in Hartha, we have developed a significant number of products which today make a major contribution to the success of the site and the entire corporate group, and will continue to do so in the future. To accomplish this, we have a team of 51 people working in this area alone in Hartha. They make up more than an eighth of the total workforce.This illustrates another focus of this site in addition to our manufacturing expertise”.

From humble beginnings, Hartha saw growth not only in sales but also in its buildings as new products soon required new production halls. This even involved complex electromagnetic coupling of the hall floor, which ensures that employees are permanently earthed, so that sensitive circuit boards and electrical circuits are not damaged by flying sparks.

WATER CIRCULATION PUMP BECOMES A SUCCESSFUL PRODUCT

Together with their colleagues at the headquarters in Neuss, the Hartha team developed the “WUP”, an electrically commutated water recirculation pump that does not require any wearprone brushes. This outwardly unremarkable component, which can be used in a wide range of applications, quickly became a million-seller. By now, the fourth generation of this little all-rounder is rolling off the production line in the largely automated Saxony factory and has exceeded total production of 100 million units. In 2004, Hartha also became the central manufacturing site for an electrically driven coolant pump – a global novelty in the automotive sector at the time. It enables demand-based control of the coolant flow in the engine and is now an internationally sought-after product, not least in view of increasingly stringent exhaust emission regulations. It is also used in new drive forms.

Another positive effect of the plant’s successful story is reflected in the increased number of employees. Today, the plant has 360 employees, with current and future products potentially offering further growth opportunities.

Major supplier

Today, the site is not only an extremely important supplier to the automotive industry. Products from the small Saxon town are to be found in drivetrains but also, for example, in auxiliary heaters and in cooling systems for electronics and seats. In addition to this traditional portfolio, the plant is constantly driving forward a comprehensive transformation of its product range. The Hartha team is also focusing on new technologies in the fields of mobility, digitalisation, home automation, and energy.

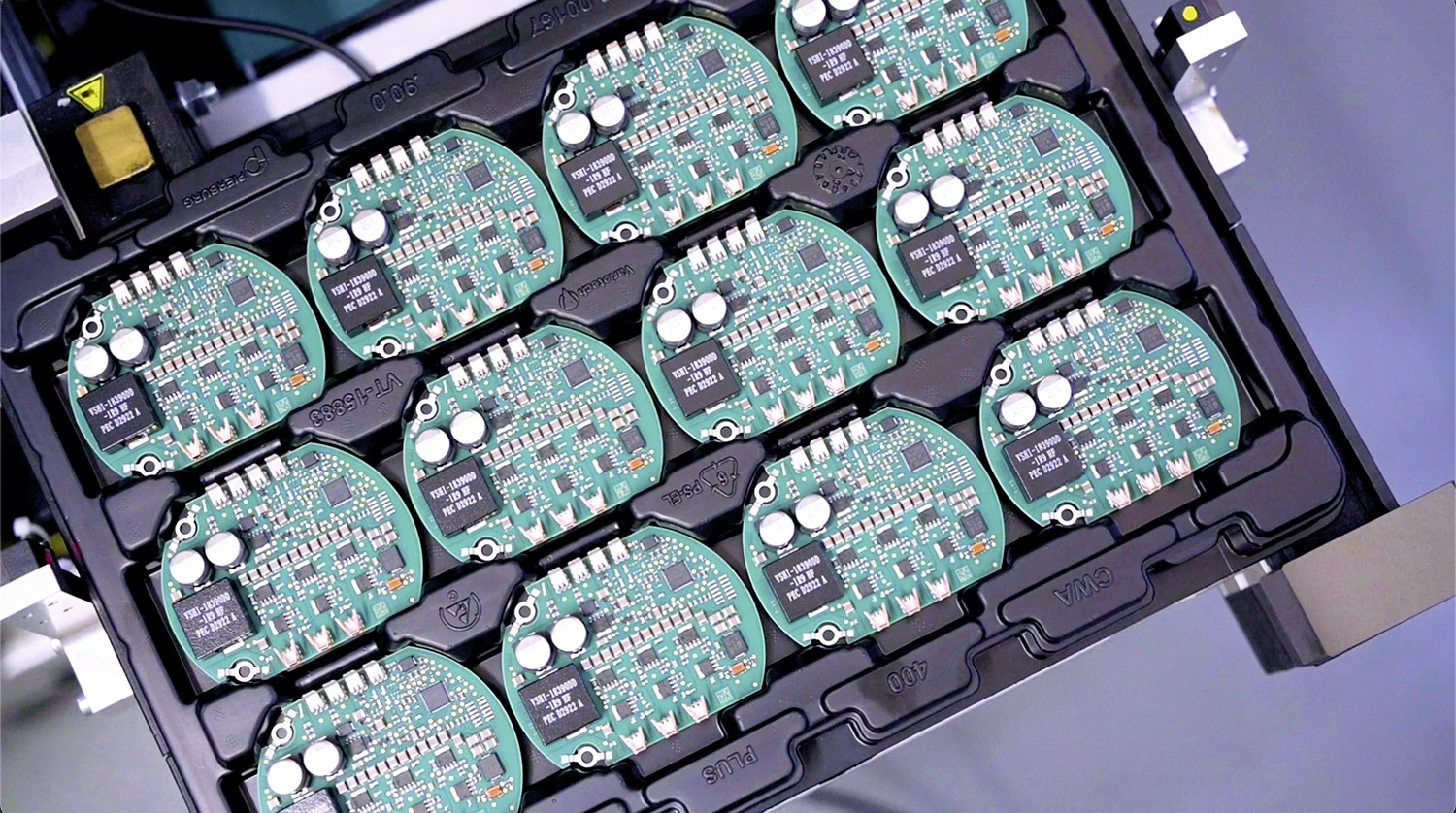

But the proverbial Saxon inventiveness and the team’s constant focus on the future go even further. Innovative miniature capacitors, the latest product from Hartha, have recently elevated the plant into a completely new era and given it a huge lead over its global competitors. For this, several million euros have been invested in a new production hall and the corresponding production lines at the site. The latter are the only ones of their kind outside the USA.

FUNDED BY THE STATE OF SAXONY

The Free State of Saxony has also recognised this internationally outstanding position and decided to subsidise the manufacture of these new progressive products with seven million euros. These tiny technical marvels consist of thousands of microscopic nano-layers and are ultimately no bigger than a matchbox. “The areas of application for our capacitors, which are mainly used in inverters, are extremely diverse, not least because of their small size”, says Schäfer. “Our exceptionally space-saving components can be used wherever direct current needs to be converted into alternating current. In addition, our existing machinery enables us to produce larger high-voltage capacitors according to customer requirements.”

The range of applications for these products, which are new to the plant’s overall portfolio, stretch from solar and wind power systems to automotive engineering and (yet again) to aerospace. Numerous other industrial sectors can also be added. This gives lasting confidence in the future development. “In Hartha, we have extensive compensation options and an innovative product range”, says the plant manager, “which enable us to maintain and expand our favourable market position even in the current difficult times within the global automotive industry”. It is therefore no surprise that the Rheinmetall plant in Hartha, Saxony, has been located on what is now Sonnenstraße (eng. “Sun Street”) since the mid-1930s. “Nomen” is not just a proverbial “omen”.

Click here to receive push notifications. By giving your consent, you will receive constantly information about new articles on the Dimensions website. This notification service can be canceled at any time in the browser settings or settings of your mobile device. Your consent also expressly extends to the transfer of data to third countries. Further information can be found in our data protection information under section 5.